How To Build A Boat Mold

how to build a boat mold

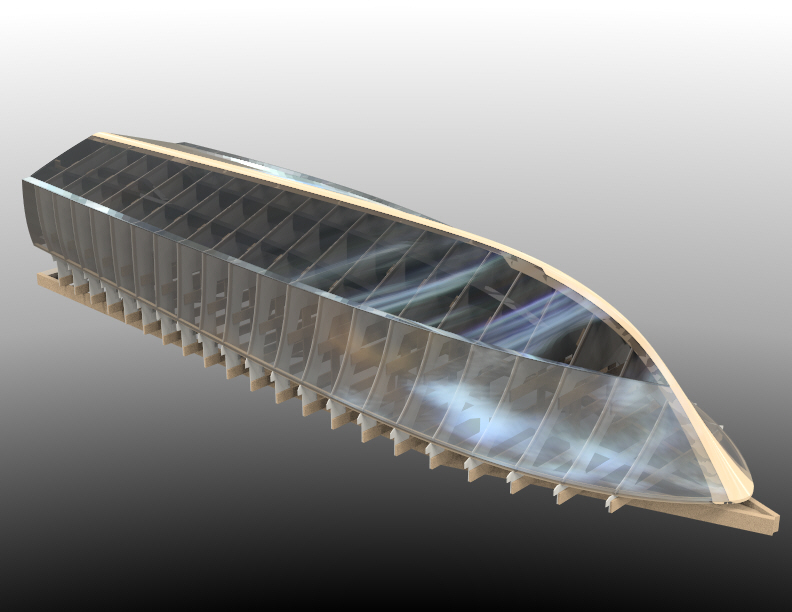

Building my 2.4 metre ( 8 feet ) dinghy hull mould from scratch.. Molds themselves, of course, must also be created. to build one fiberglass boat, it is often said, you must in fact build two boats: the finished product and the mold from which it springs. with a female mold, you normally build three boats to get one--first a male plug on which the female mold is formed, then the mold, and finally the boat itself.. Designs and building techniques have changed but the mold remains the key to a fiberglass boat’s construction, appearance, and performance. manufacturing the mold begins by building the plug. a flying bridge plug, for example, can be made from wood that is shaped to resemble the actual bridge with its side wings, integral seating, and other.

how to build a boat mold With fiberglass boat building, however, the major components of the boat – the hull, deck, liner, and large parts like consoles—are molded from fiberglass. usually, this means starting with a female mold. the mold is first sprayed with gelcoat, then fiberglass cloth is applied, and then resin is used to saturate or “wet out” the fiberglass.. Generally speaking, we build all our molds with flanges, assuming that at some point we will want to use them in a closed-molding or vacuum infusion process. it is much easier to build flanges into the fiberglass mold from the start than to do it later. mold flanges should be a minimum of 6" with 8" being preferable..

0 comments:

Post a Comment